FACILITY

We take pride in our reputation for excellent customer service, quality products, and innovative solutions.

Design

A highly innovative and experienced design team makes sure the international standards are adhered to throughout the process.

Design Capabilities & Facilities

Our team have the capability to implement customer requirements over the entire range of a project, from basic design to detailed engineering. The team has proven that through various product design development to cater for the requirement and specifications of Oman authorities. All designed products has been tested inhouse and subjected to complete type tests to meet international standards and local specifications.

Advanced Design Activities

Our design team is working with 2D/3D drawings with latest version of Autodesk Inventor software, which generates error free accurate drawings, Pictorial view of each part before manufacturing the products, presentations show the way to assemble the components and automation of drawing preparations.

Short Circuit Design Capabilities

Short circuit proven designs to verify Electrical and Thermal Test and to prove that transformers meet customer requirements as per Latest International Standards.

Manufacturing

The core employs a mitred step-lap design ensuring minimum noise and loss level

The Core

Each transformer core is produced by using interleaved laminations of cold rolled, grain orientated, low loss electrical sheet steel conforming to BSEN 10107 and other international standards. The core employs a mitred step-lap design ensuring minimum noise and loss levels with uniform flux distribution throughout the magnetic circuit.

Windings & Insulation

All windings are manufactured to exacting standards in order to maintain strict dimensional tolerances. Clamping to a pre-determined load pressure during manufacture ensures that each winding is able to withstand the excessive axial forces which may result from external and short-circuit events.

All principal components of insulation are prefabricated from electrical grade insulating board and are pre-shrunk to ensure electrical and mechanical stability throughout the temperatures found in operational service.

The completed core-coil assembly is dried in a PLC controlled vacuum drying chamber

Each core-coil assembly is rigidly braced using steel frames, distributing the axial clamping forces around the entire circumference of the windings. Optimum dielectric strength is achieved via processing in accordance with rigorous in-house quality procedures.

Tanking

The completed core-coil assembly is dried in a PLC controlled vacuum drying oven. The dried active parts are fitted into the transformer tank and oil is filled under vacuum through a filtration machine.

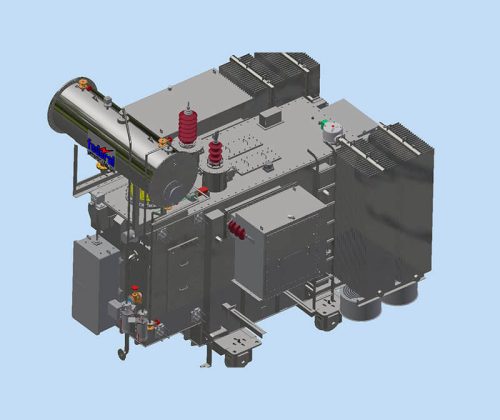

Final Assembly

When the tanking process is completed all accessories are fitted.

- Bushings (Oil to Oil, Oil to SF6, Oil to Air Condenser, Porcelain, Plug-in type, Monoblock)

- Conservator with hydro compensator (Air bag)

- Maintenance free breathers

- Hydran/Callisto online gas monitoring devices

- Other customer specific fittings/instruments

After the final assembly process is completed the oil is filtered again and allowed to settle before the transformer is moved to the test bay.

Testing & Inspection

The testing lab is fully equipped with state-of-the-art apparatus to carry out routine and type tests

Test Facilities Available

Routine test as per IEC 60076

- Measurement of Winding Resistance.

- Measurement of Voltage Ratio & Check of Phase Displacement

- Measurement of Short Circuit Impedance & Load Losses.

- Measurement of No-Load Losses and Current.

- Separate Source Ac Withstand Voltage Test.

- Short Duration Induced Ac Withstand Voltage Test.

- Main Tank Oil Pressure Test.

- Oil Breakdown Voltage Test (BDV).

- Tests on Paint Works (Dry Film Thickness)

- Functional Test of Accessories, Control Circuit & Wiring Check.

Type and Special Tests

- Temperature Rise Test

- Acoustic sound level

- Zero phase sequence

- Harmonics of No-Load Current

- Capacitance and tan delta measurement on windings and bushings

- Magnetic balance and magnetizing current test

Quality Standards

- IEC 60076-1 General

- IEC 60076-2 Temperature rise for liquid immersed transformer

- IEC 60076-3 Insulation level, dielectric test and external clearance in air

- IEC 60076-4 Guide to the lighting impulse and switching impulse testing power transformer and reactors

- IEC 60076-5 Ability to withstand short circuit

- IEC 60076-6 Reactors

- IEC 60076-7 Loading guide for oil immersed power transformer

- IEC 60076-8 Application guide

- IEC 60076-10 Determination of sound level

- IEC 60076-'10-1 Determination of sound level - application guide

- IEC 60076-11 Dry-type transformers

- IEC 60076-12 Loading guide for dry-type power transformers

Quality Assurance

“We are committed to manufacture Distribution and Power Transformers, Dry Type Cast Resin Transformers, Special Transformers, Packaged Sub Stations and provide services which consistently satisfy the needs and expectations of our shareholders, customers, employees and Society. Federal Transformers and Switchgears LLC believes Quality of Product, safety and health of its employees and others, preservation of the environment is both an individual and management’s responsibility and therefore will demonstrate commitment to QHSE issues by:

Quality Management

- Ensuring design, engineering and process improvements and practices to enhance quality of product, reduce negative environmental impacts, waste, energy, raw material consumption and prevent pollution;

- Striving to achieve continual improvement through implementation and review of the QHSE management system and related performance;

- Provision of appropriate resource to effectively manage and improve QHSE Risks throughout the lifecycle of the organization and projects;

- Encourage Employee involvement in implementation of QHSE policy

- Understand and comply with applicable Sultanate of Oman Legal, Regulatory & Statutory requirements;

- Prevention of Injury, Illness and Environmental pollution, thus enhancing employee’s health and well-being by Establishing and enforcing safe and environmentally sound method of work;

- Identifying Hazards/Aspects and assessing the Risks/Impacts in all the stages of operation and shall be eliminate hazards and reduce OH&S risks;

- Implementing appropriate Preventative and Protective measures;

- Providing and maintaining safe plant and work equipment;

- Ensuring that technical competence is maintained through the provision of training as appropriate to raise awareness of QHSE issues at work;

- Promoting awareness of QHSE and of good practice through the effective communication of relevant information;

- Ensure establishment of framework for setting the OH&S objectives, QHSE Targets and objectives and monitoring, measurement and reporting programs and continually improve QHSE Performance;

- Communicating this QHSE Policy to all the employees, interested parties, stakeholders and public;

- Reviewing this policy annually to monitor its effectiveness and to ensure that it reflects changing needs and circumstances.

- Ensuring the commitment to consultation and participation of workers, and, where they exist, workers’ representatives.

While Maintaining efficiency and Profitability”

- Calibration from NABL Accredited external laboratory

- Continual improvements by implementing proven global standard practices such as

- Six Sigma Methodology

- 7 QC Tools

- 8D Analysis

- 5W2H Analysis

- COPQ Analysis

FTS now is manufacturing and supplying transformers to all Government sectors, utility companies & oil and Gas companies.